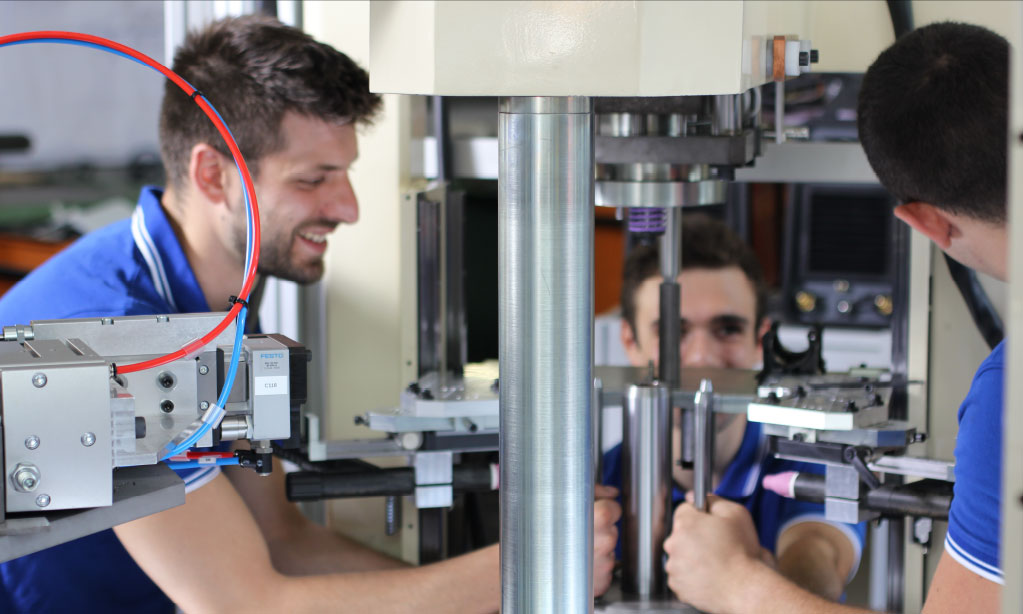

Flexible processes for electric motors production

We guarantee high standards for performance, quality and timing targets, following your special needs. From development to installation and over, we follow our machines life long.

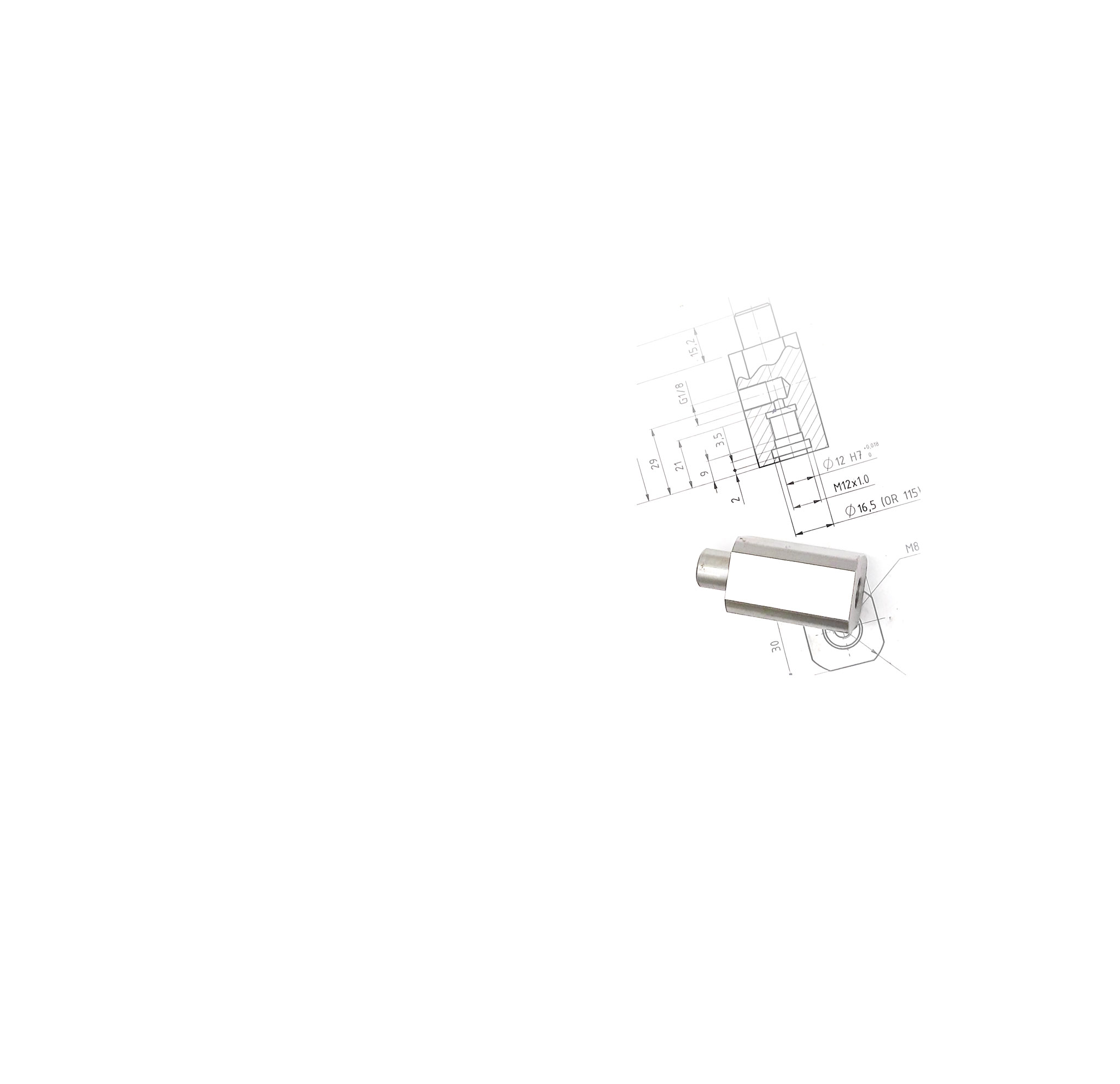

Our machines

The solution comes from the listening of our Customers and everytime is unique and customized

We listen to you, we focus on your production goals and we come with you towards the winning solution thanks to automatized processes invented and developed following your needs. We put in place all our technologies to satisfy all your requirements.

PROCESSES

The only company in the world with this expertise

![]()

Stacking

![]()

Joining

![]()

Inspecting

![]()

Assembling

From over 70 years for electric motors and generators

DEMA gained its experience supplying leader companies all over the world in the automotive field, home appliances and tools, and industrial field.

They chose us

Get our newsletter

Let's keep in touch! Get our newsletter for further and recurring updates about our activities and the most innovative technology.