Assembling

Assembling

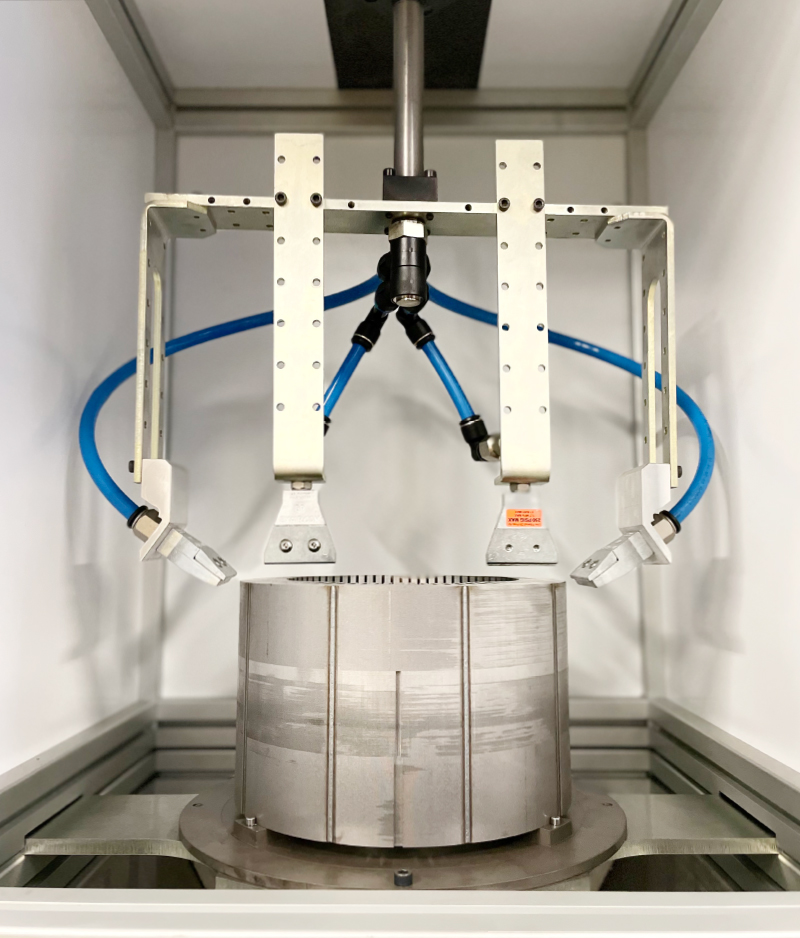

To complete the production process of stator and rotor stacks further operations could be necessary.

Do you need further operations on your rotor or stator stack? Do you want to automatize one or more of the following processes?

- MAGNETS INSERTIONS

- GLUE DISPENSING AND POLYMERIZATION

- SHAFT NOTCHING

- END FIBERS INSERTION

- COMMUTATOR INSERTION

- MECHANICAL DEFORMATION OF BURR AND COMPONENTS

- LUBRICATION AND RUSTPROOF DOSING

- PLASTIC MOLDING MACHINE FEEDING

- STACKS CLEANINGS

- PACKAGING

Our machines allow you to carry out the operations that you need, and our experience, ensures you make them in the best ways.

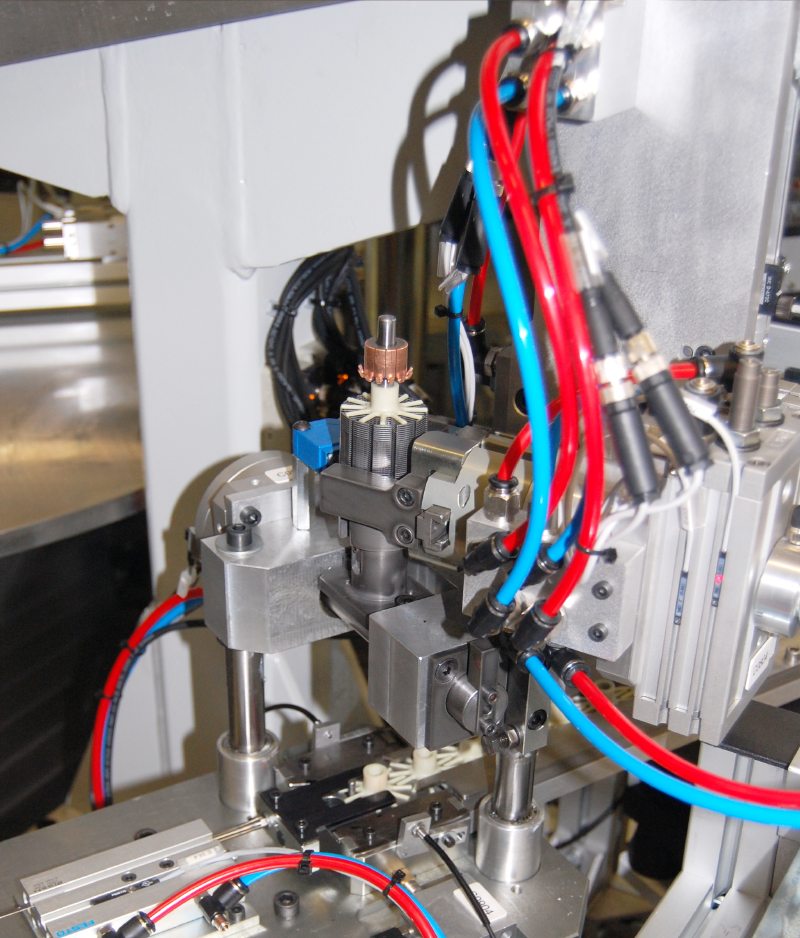

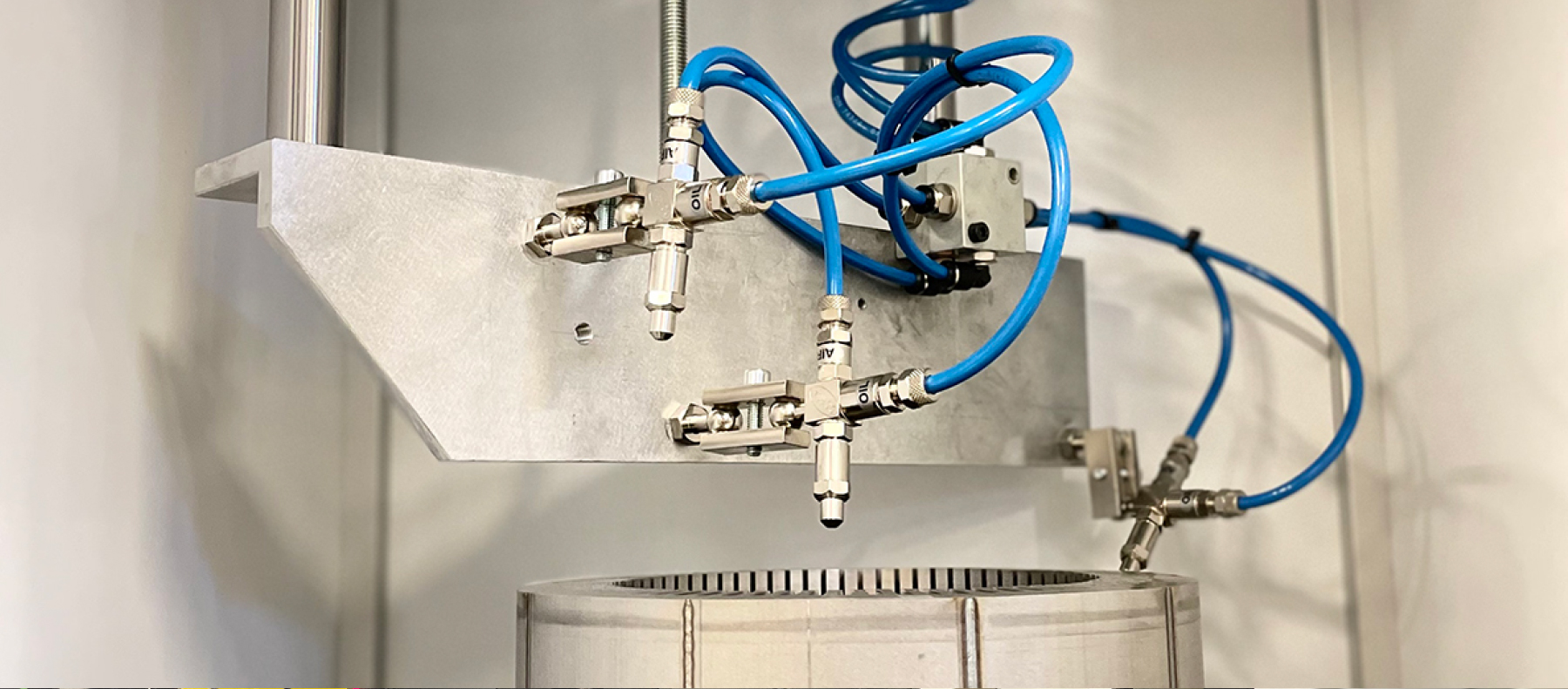

Shaft notching

We can notch the shaft directly during the in-line process with a lot of advantages both on the technical and economic sides. During the production phase, you would have full control of the friction force during the shaft insertion to complete the rotor.

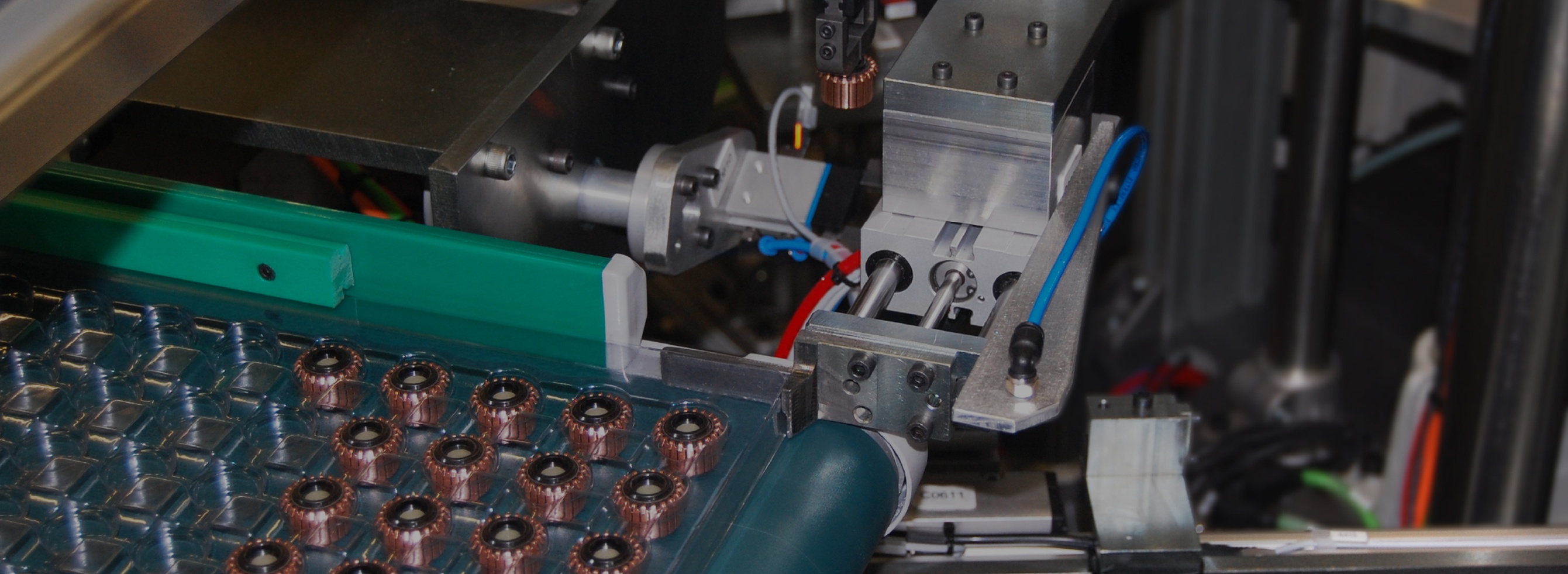

Magnet insertion

Dema machines can insert magnets of different shapes and dimensions (already or not magnetised). The fixing can be done by mean of glue or mechanical deformations.

Other processes

![]()

Stacking

The activity of selection and formation of the rotor or stator stack starting from loose lamination.

![]()

Joining

The competence of joining the laminations and holding them together to form a rotor or stator stack.

![]()

Inspecting

Execution of dimensional automated controls both mechanical and visual on specific features.

Do you have a process to automatize?

We are eager to hear and discuss with you to find together the most suitable solution for your needs.