Joining

Joining

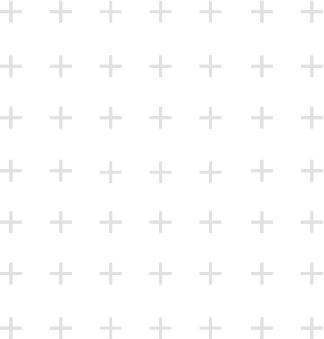

Joining: the competence of joining the laminations and hold them together to form a rotor or stator stack.

Our Machines can do the process defined for the stack production and Dema can supply its consulting to define the best process for each application. The most frequently used processes are laser welding, TIG or MIG and glueing with BackLack laminations or Quick self bonding.

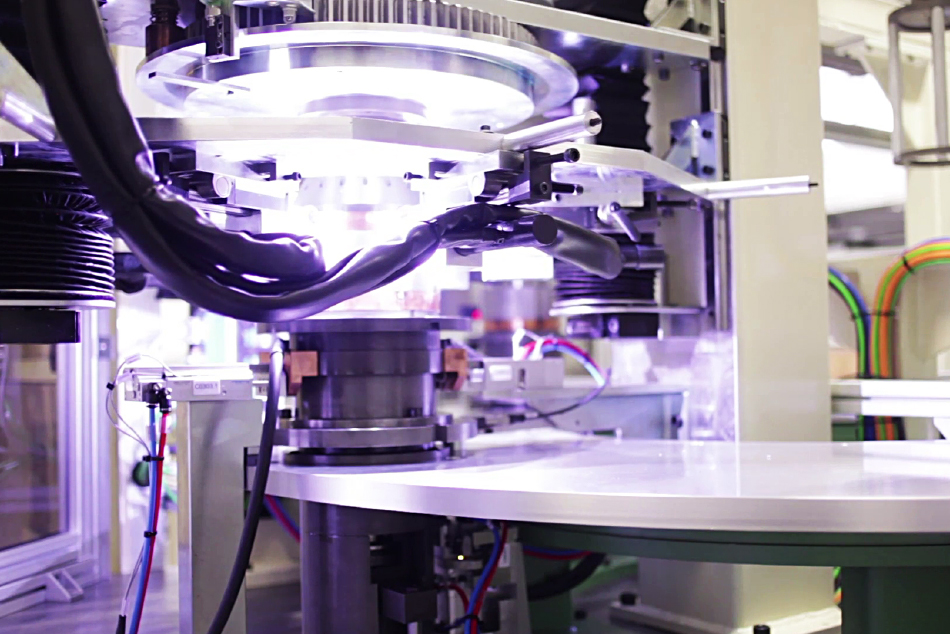

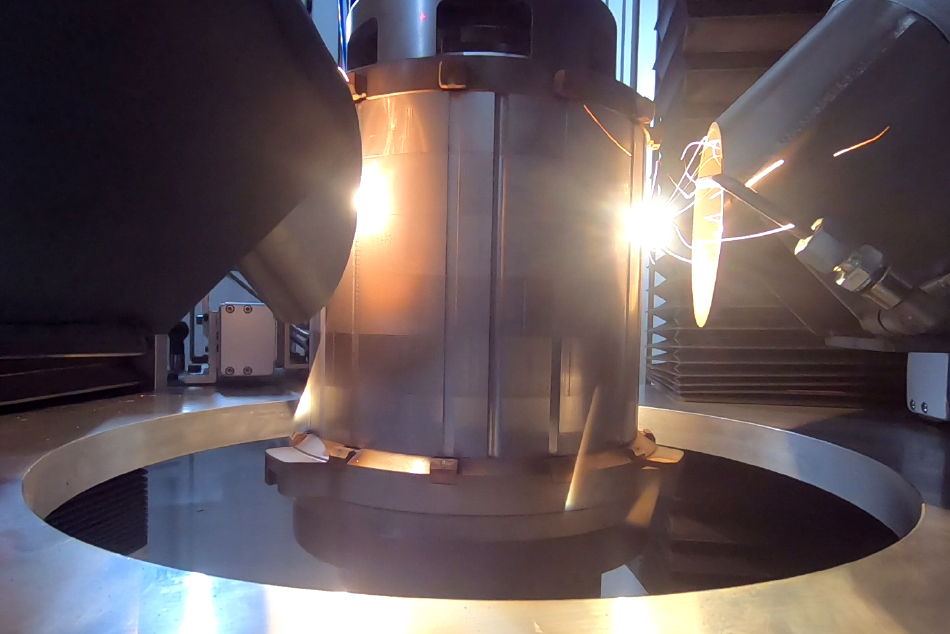

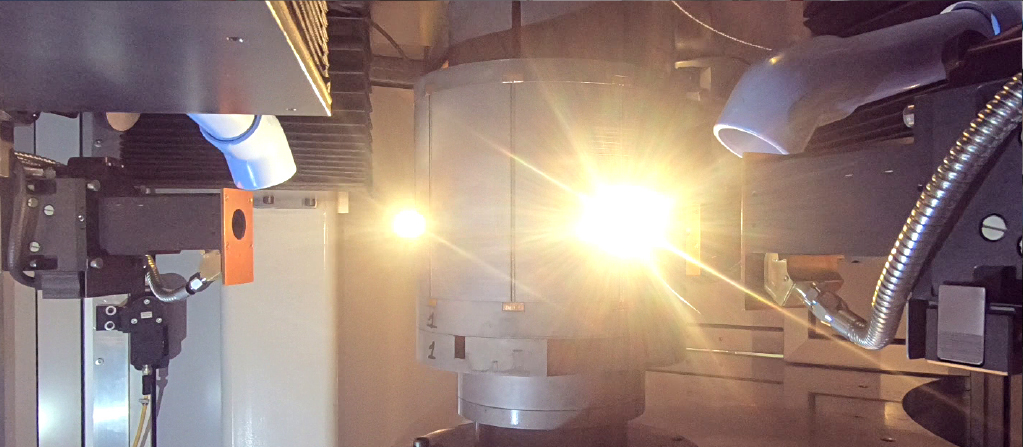

- WELDING

- SHAFT INSERTION

- POLIMERISATION (BACKLACK, GLUE)

- RIVETING

- REPRESSING

- CLEATING

DDLock

The innovative method that joins both welding and gluing advantages, consists of our hybrid patented solution called Dema Double Lock.

Stacking factor

The right "stacking factor" is determined and ensured by the repressing carried out by our machines in case of interlocked stacks.

Other processes

![]()

Stacking

The activity of selection and formation of the rotor or stator stack starting from loose lamination.

![]()

Inspecting

Execution of dimensional automated controls both mechanical and visual on specific features.

Do you have a process to automatize?

We are eager to hear and discuss with you to find together the most suitable solution for your needs.